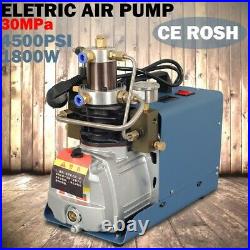

30MPa Air Compressor Pump 110V PCP Electric 4500PSI High Pressure System R-ifle

30MPa Air Compressor Pump 110V PCP Electric 4500PSI High Pressure System R-ifle

30MPa Air Compressor Pump 110V PCP Electric 4500PSI High Pressure System R-ifle. Take out the product; install the hose at the air outlet. Note: gasket is needed, or air leakage might exist. Connect 2 cold water pipes and connect them to the water pump. Note: the lower pipe connected to the water pump is water inlet; sinking pump is used in this product. The water pump should be immersed in water for using. Install the pressure relief valve screw; pressure relief valve screw is installed at the pressure relief hole under the hose. The blow-down valve is installed at the. Drain outlet of the first air chamber block. Immerse the water pump in water and switch on the power. Connect the container need to be inflated, make sure the connection is correct. Screw up the screws of the blow-down valve and pressure relief valve. Switch on the power ant the machine operates. Note: when the machine is operating, the water must operate correspondingly, or the product might be damaged due to overheated, personal harm may even occur. After the inflation is completed, screw of the pressure relief valve should be firstly loosen, then the power is to be switched off, by doing so, high pressure. Air backlash caused due to sudden failure of power supply would be avoided, which could lengthen l-ifetime of the product, as well as discharge high pressure air in the machine. Please use the power supply according to the parameter table. If abnormal noise occurred during the using of the product, please stop using it instantly and check the cause. The product should be placed at a place that it couldn t be t-ouched by children. Please do not use it in moist and f-lammable place. Please do not modify it arbitrarily, disassembling and repair by non-technical personnel is not allowed. Make sure the socket could withstand a currentgreater than 8A before using it, or the circuit might be burnt, the product might be damaged and the dangers may be caused due to overload of the socket. Please do not t-ouch the head section after the machine was just being used, so as to not beburnt by high temperature. Please do not leave without authorized, or the product might be damaged by increasingly rising pressure, sustained overload motor, even halt due to the operation pressure has reached but it is not turned off timely. When it is used for inflating slightly larger container, the cooling water should be changed every 30 minutes, in this way, the cylinder. Temperature could be better controlled. The machine oil should be checked regularly, make sure the oil level is above the upper edge of the red point. If color of machine oil becomes dark and black, it should be changed in time. Seventh generation hardcover version. 40-50L/MIN; 1.5-1.8CFM. Manual stop/automatic stop(for optional). ISO VG46 or AW 46. 8mm quick connect fitting. 30Mpa Electric Compressor Pump. The item “30MPa Air Compressor Pump 110V PCP Electric 4500PSI High Pressure System R-ifle” is in sale since Friday, August 7, 2020. This item is in the category “Business & Industrial\Hydraulics, Pneumatics, Pumps & Plumbing\Pumps & Pump Accessories\Other Pumps”. The seller is “zanalch-73″ and is located in Shenzhen. This item can be shipped to United States.

- Model: Seventh generation hardcover version

- Modified Item: No

- Custom Bundle: No

- California Prop 65 Warning: Does not apply

- Power Rating: 1.8KW

- Inflating Speed: 2800R/Min

- Noise: MAX 85DB

- Air Flow Rate: 40-50L/MIN; 1.5-1.8CFM

- Working Pressure: 100-300BAR; 1500-4500PSI

- Cooling System: Water Cooling

- Type: Air Compressor Pump

- Compression Stage: Two Stage

- Lubrication Mode: Splash Type

- Material of Cover: Cast Aluminum

- Shout down: Manual stop/automatic stop(for optional)

- MPN: Does Not Apply

- Pressure indicate: Gauge

- Filtration: Water/oil separator

- Lubricating oil: ISO VG46 or AW 46

- Air hose connection: 8mm quick connect fitting

- Brand: Unbranded